how to measure piston ring thickness|piston ring end gap chart : supermarket The coating thickness measurement tool measures the remaining life time of coated piston rings:-Liner time scale: ~1000 Rh-Measurement time: ~15 minutes/liner. CTM is ideal for condition based monitoring of piston rings in 2 .

Resultado da Season 15 of The Joy of Painting with Bob Ross features the following wonderful painting instructions: Splendor of Winter, Colors of Nature, Grandpa’s Barn, Peaceful Reflections, Hidden Winter Moon Oval, Waves of Wonder, Cabin by the Pond, Fall Stream, Christmas Eve Snow, Forest .

{plog:ftitle_list}

webclient . Sign in to download and access your account information. If you are not yet a customer, please sign up.

piston rings by size chart

A micrometer is the most common and accurate tool for measuring piston ring thickness. Here’s how to use it: Clean the ring: Remove any dirt or debris from the ring surface using a clean cloth. Position the micrometer: Place the ring between the anvil and spindle of . Bill McKnight at MAHLE Aftermarket teaches you how to measure ring face width, ring radial wall thickness and intended bore size.

piston rings by dimension

Place the piston ring on a flat surface and measure its thickness using a micrometer or vernier caliper. Place a dial indicator on the piston and position its tip at the .

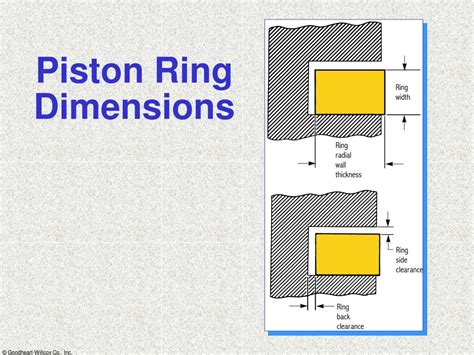

This dimension refers to the ring’s thickness as viewed from the side of the piston. This 5/64-inch thickness (0.078-inch) required a .

With the rings off, measure the axial height (this is the thickness of the ring) and radial width (the width of the ring from the outer edge to the inner edge) of the oil ring .

The coating thickness measurement tool measures the remaining life time of coated piston rings:-Liner time scale: ~1000 Rh-Measurement time: ~15 minutes/liner. CTM is ideal for condition based monitoring of piston rings in 2 .

Figure 1: Actual coating thickness of a top piston ring Actual piston ring wear & coating thickness As shown on figure 1, the wear of the top piston ring is not worn symmetrically. Because of this, it is important to measure the piston . In this brief video, we demonstrate a few methods to measure the axial (thickness) and radial (depth) dimensions of the piston ring grooves. The rings need p.

On the contrary, a 2.0 mm thick ring can also fit a piston groove of 1.98 mm (5/64"), and a 4.0 mm thick ring can also fit a piston groove of 3.97 mm (5/32"), and vice versa. Piston ring radial thickness. The radial thickness of the piston ring can be easily measured with the vernier caliper, as well. However, this applies to a brand new piston .

piston ring end gap chart

Measure the gaps that are the piston ring grooves. Both width and depth will need to be discovered so that when you install a new set of piston rings, they will fit correctly. . For the family car it is better to use the original sized piston rings instead of changing the size of the rings to a larger thickness. Instead of machine honing, try .Inside diameter, cord thickness, standards. and then there is matching the groove dimensions. . difficult, risky or sometimes impossible to determine the correct O-ring size. It is not recommended to determine an O-ring size by measuring a used O-ring. . O-ring in the piston: the O-ring is best stretched around the groove in the piston; The ring must be perfectly square in the bore to get an accurate measurement. Avoid Ring Gap Related Issues. . Using a tapered piston ring compressor sleeve in the correct bore size helps ensure the pistons are installed without damaging the rings. . some pistons have the same thickness top and second rings. Pay attention to the shape and . Measuring piston ring thickness is a critical step in assessing the health of your engine. It plays a vital role in maintaining proper compression, reducing friction, and dissipating heat.By understanding how to measure piston ring thickness accurately, you can prevent costly repairs and ensure optimal engine performance.

---Seafarers - Technical Guide for MarineEngineers--. Using a piston ring squaring tool sets the piston rings at a consistent depth because the user can pull the ring up to the surface of to tool to ensure that the piston ring is square to the .In order to check ring gap, the rings should be placed at the lowest possible part of the cylinder (below ring travel area) as this is the portion of the cylinder that is unworn and which the ring is sized for. Checking ring gap in the worn portion of the cylinder will show a gap increase in direct relation to the amount of cylinder wear present.

The graphic shows the relative size comparisons in both radial width as well as ring thickness between the ring sizes tested. While 1/16-inch rings might not sound that different from 1.0mm rings. . The important factors to analyze would be the bore finish before and after each piston ring test along with measuring the engines blow-by during .

Selecting piston rings based on tension properties can get a little tricky. Low tension improves horsepower but higher tensions keep the engine healthier. Experts at the School for Automotive Machinists (SAM) and Total Seal offers tips .

Piston rings play a crucial role in maintaining optimal engine performance by sealing the combustion chamber and regulating oil consumption.Ensuring the proper tension of these rings is essential for efficient engine operation. This blog post will provide a detailed guide on how to measure piston ring tension, empowering you with the knowledge to optimize .How to Measure Piston Ring End Gap. In order to measure your ring end gap, once the ring is located in the bore, you need to make sure that it’s an equal distance down from the top on all sides — or in other words, it’s square. This . If you can’t measure the piston at the wrist pin centerline, the next best approach is to measure the piston rock at both ends — up and down and then average the two. So if the piston measures 0.020-inch rocked down and . The piston ring is connected to the sensor through reasonably rigid member. The underlying assumption here is that there is no elastic deformation of the piston ring due to the hydrodynamic pressure. The fundamental sensor to measure oil film thickness used in this setup is a set of strain gauges., – It is possible to measure oil film .

The piston rings are fixed into the grooves of the piston to maintain a good seal between the piston and the cylinder wall. Piston rings are made and classified based on their functionality and usage. The main purpose of the piston ring is to seal the chamber, which is the area where the piston is traveling in a two-stroke or four-stroke engine.. The piston ring is a . There are a lot of piston ring material types to consider for your next engine build. Our buyer’s guide will help you choose the right ones. . Standard Tension: Varies by oil ring thickness, so a standard tension 3/16 oil ring is not the same tension as a standard tension 3.0mm oil ring. The thicker the oil ring, the higher the standard .

How to measure piston diameter (using a micrometer) and piston ring side clearance and end gap (using a feeler gauge). Ultrasonic approaches have recently been explored to measure piston ring oil films. 35 . The film thickness of each piston ring is compared and the variation between the different strokes in the engine cycle at various speeds and loadings are explored. Novel work was performed to quantify the residual lubricant film thickness over an . When you shop for high performance piston ring sets, you’ll no doubt find there are many different sets and styles available (no big secret). And many of these ring sets are designed to be hand-fit to each cylinder bore. Typically, file-fit rings are designed so they measure 0.005-inch oversize (obviously larger than the cylinder bore size). By design, it’s up to you to . A good rule of thumb for a high- performance street engine is engine bore byx 0.0045 -inch for the top ring, bore byx 0.0050- inch for the second ring, and a minimum of 0.015- inch for the oil ring rails. To measure piston ring end gap, each ring is inserted a predetermined depth, achieved here using a Summit Racing Piston Ring Squaring Tool .

export Hot Tack Testing

Ring thickness affects how much force the ring pushes against the cylinder wall. A thicker ring seals better but may wear out faster. . Put the piston ring in the bore and measure the gap with a feeler gauge. 2. Check the gap against the engine’s recommended range. 3. If too small, file or grind the ring ends. Replace if too large. 4. Keep .

Measure the Ring Thickness: Use a caliper to measure the thickness of the piston ring at several points. Record the measurements and calculate the average. 4. Calculate the Ideal Gap: The ideal gap is typically a percentage of the cylinder bore diameter. The space behind the ring is calculated by subtracting the ring radial wall thickness from the root depth of the ring groove in the piston. Or, you can measure the inside diameter of the ring installed in a cylinder bore, and subtract that from the outside diameter of the bottom of the ring groove in the piston. Let’s say you have a ring that .

Piston ring gap is a word many enthusiasts know about, but few understand. Find out more about getting it right, and the benefits. Skip Content. . So if it takes 15 turns to establish the proper gap for a second ring, then start with a new ring at around 12 turns and measure the gap. Sneaking up on the clearance takes more time, but ensures .

piston ring dimensions guide

piston ring clearance chart

piston ring chart

web23 de abr. de 1999 · The VHL tumor suppressor gene on chromosome 3p25.5 is mutated in most sporadic clear cell renal carcinomas and in VHL disease, an autosomal dominant familial cancer syndrome that predisposes affected individuals to a variety of tumors ().The VHL protein is expressed in most tissues and cell types and appears to perform multiple .

how to measure piston ring thickness|piston ring end gap chart